Kp Ki Kd Values

Set Ki Kp and Kd to 0. These values are immediately loaded onto your boards memory but not the firmware.

The Effect Of Increasing Each Of Controller Parameters Kp Ki And Kd Download Scientific Diagram

Here is the matlab code used to simulate PID The below code is written by me.

Kp ki kd values. C pidKpKiKd T feedbackCP1. Kp is free PI Proportional-integral. After that in the PID Controller block in Simulink write Kp Ki Kd and N to the parameters.

Tune Ki to increase the speed of the system. TLE7242 KI KP Application Note Calculating the values of KP and KI V BAT 14V R c 56 Ohm L c 10 mH R sense 02 Ohm f CLK 20 MHz f PWM 4 KHz 5 Calculating the values of KP and KI 51 Setting ζ and ω n Although the control system is not a tr ue low-pass second order system due to the presence of the open loop zero the parameters ζ and ω. Kp and Ki are free PD Proportional-derivative with first-order filter on derivative action.

The following m-code plots the step response. My limitation is I always have to connect my Arduino to pc and change kp ki or kd values that is I have no remote control available currently. In Frequency Domain after taking Laplace Transform of both sidesthe control input can be represented as.

By fluorescence quenching isothermal titration calorimetry or surface plasmon resonance. Send the M500 command to save and store these values to your mainboard. Kp 05 Ku For a PI loop.

For a P only loop. These constants are the tuning values and represent how much the process control relies on the P I and D. M301 P1956 I071 D13426 In the case of multiple extruders E0 E1 E2 these PID values are shared between the extruders although the extruders may be controlled separately.

A change in temperature. The term Ki is used whenever this binding constant is measured through inhibition kinetics while Kd is preferred when the binding is measured more directly eg. StepTt C 1 Kp Ki --- Kd s s with Kp 350 Ki 300 Kd 50 Continuous-time PID controller in parallel form.

Kp 045 Ki 0009 KuTu For a PID loop. Wait for the terminal to finish cycling and echo the P I and D values. So the ideal PID values for our plant is Kp 200 Ki 300 and Kd 10.

A good overview of PID controllers with links for more specialized related issues such as those discussed below is in. Calculating KpKiKd values for the arduino PID library given transfer function. I have calculated the transfer function for a DC motor and I want to use the arduino PID library to control that motor.

Luckily it turns out that the. I defined the unknown parameters as symbolic and then obtain the numerical values with the vpasolve function. Kp Kd and Tf are free PID Proportional-integral-derivative with first-order filter on.

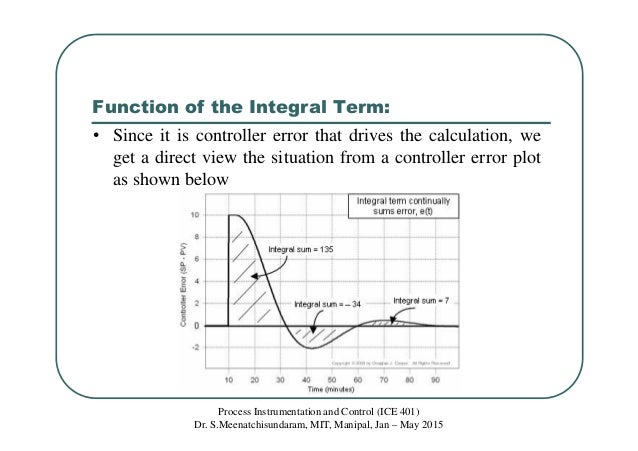

Ki is fixed to zero. The integral accounts for the sum of error over time. Ki 0075KuTu so its units.

Is there a way to use this transfer function to find out what my ideal Kp. Note that at the end the symbolic controller parameters are replaced with their numerical values. An increase in the integral term Ki means that the error is increased over time.

207 1 1 silver badge 7 7 bronze badges. Kp 06 Ki 002 KuTu Kd 45KuTu These are rule of thumb calculations. The system being controlled.

A PD controller would remove the iTerm from the return value. Tf is fixed to 1. Kd is fixed to zero.

As far as tuning goes it is similar to what Illegal Immigrant said. Frequency Domain Representation of PID Controller. Tf is fixed to 1.

Change in output secondcelsius. System October 12 2013 728am 1. What I did is a simple equation solving.

After that in the PID Controller block in Simulink write Kp Ki Kd and N to the parameters repsectively. Solving the simultaneous equations yields Kp 175 and Ki 65. If the EEPROM is enabled save with M500.

Each of the three parts have a constant coefficients Kp Ki and Kd. These will read as kP kI kD. Ki 12KuTu so its units.

Repeating previous answers IMHO the magnitude of the gains Kp Ki and Kd will depend on the characteristics of the process ie. Change in outputcelsius second. Ki and Kd are fixed to zero.

Kp Ki Kd values to an PID controller. So please let me know if you find any bugs. One good candidate is s 3 18s 2 18s 6.

Where Kp is the Proportional GainKd is the Derivative Gain Ki is the Integral Gain of the controller. Take the location of the poles in the complex plane discretize this plane and each of the poles calculate the response and find the maximum and minimum values and the use of graphics on the complex plane creating a map of an outline a direct visual indication of the values of the poles are obtained from. Kd causes the robot to react faster as the error increases.

An increase by double the change in the robots heading would take place if the robots heading is doubled in error from the previous feedback result. Since Kp is proportional to DA where D change in output which we take 0 to 100 since its relay method. Importantly Ki values only accurately report a binding constant when the kinetic mechanism is correctly identified.

What I did is a simple equation solving. The Kp Ki and Kd values can be entered with. Kp has unit.

Reduce oscillation and overshoot by tuning Kd. Tune Kp until oscillation occurs. I defined the unknown parameters as symbolic and then obtain the numerical values with the vpasolve function.

The above process is known as manual tuning of PID. Note that at the end the symbolic controller parameters are replaced with their numerical values. Good Luck 8.

For one process the Kp Ki and Kd values might be one set value but when the process is changed to a different motor for example the set points might be different. Follow edited Aug 8 20 at 1748.

Kp Ki And Kd Values For Experimental And Simulation Download Table

Kp Ki Kd Values That Change During The Online Tuning Process In Download Scientific Diagram

Class 20 Effect Of Kp Ki Kd And Pid Control Mode

Performance Parameters For Different Values Of Kp Kd Ki Download Table

Chr 1 Method Of Calculating Kp Ki And Kd 16 Download Table

The Target Temperature With The Various Kp Ki And Kd Values Download Scientific Diagram

Pid Tuning Kp 0 10 Ki 0 05 And Kd 0 Download Scientific Diagram

Class 20 Effect Of Kp Ki Kd And Pid Control Mode

Tidak ada komentar untuk "Kp Ki Kd Values"

Posting Komentar